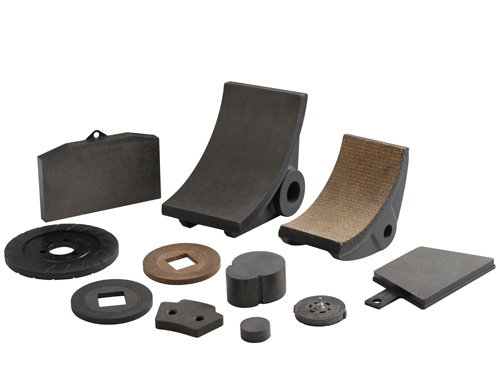

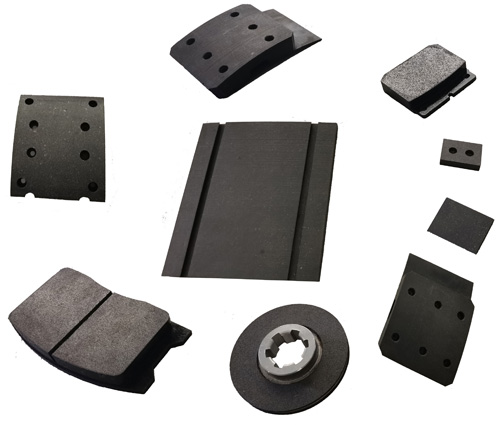

We offer the most complete selection of off-highway friction application available on the OEM and the aftermarket.

We provide suitable brake linings, blocks, pads, segments for construction machinery, agricultural machinery, dredging equipment, power transmission equipment, workboats, brake motors, etc.